IIR

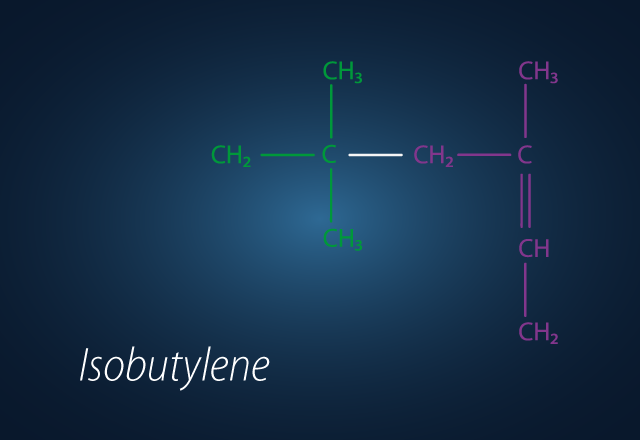

IIR Rubber, commonly known as Butyl and Halobutyl rubber, is an essential type of elastomer widely used across various industries. IIR is produced by the copolymerization of isobutylene and isoprene. The chlorinated and brominated versions of butyl rubber offer broader cross-linking flexibility and better compatibility with other elastomers such as Natural Rubber (NR) and Styrene Butadiene Rubber (SBR). Different types of IIR vary based on molecular weight (Mooney Viscosity), similar to other elastomers. Its chemically inert structure allows high-temperature mixing, enabling the production of more flexible vulcanizates through heat treatment.

IIR provides excellent gas impermeability. Its extremely low permeability to air and gases makes it a preferred material for sealing applications.

Its flexible structure offers high vibration damping capacity. Additionally, due to its superior resistance to ozone and weathering, it is suitable for long-term outdoor use. IIR also exhibits high resistance to moisture, water vapor, and various chemicals.

Halogenated butyl, i.e., chlorinated and brominated butyl, delivers exceptional performance in terms of air and gas impermeability, vibration damping, and aging resistance.

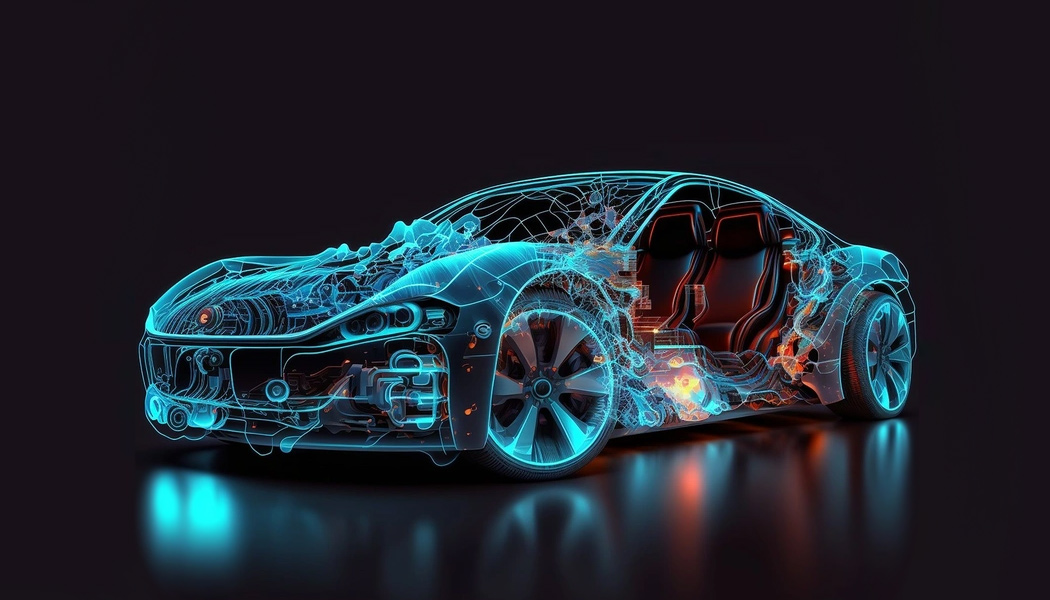

These properties make IIR an indispensable material for automotive, pharmaceutical, construction, and numerous industrial applications.

Applications

• Tire Inner Liners

• Tire Sidewalls

• Sports Equipment

• Gas Masks and Chemical Protection

• Pharmaceutical Stoppers

• Chewing Gum Production

• Conveyor Belts

• Engine Mounts

• Hoses

• Sealing Strips

• Gaskets

• Tank Linings

HARDNESS RANGE:

30 to 80 Shore A

- Isobutylene-Isoprene (Butyl)

- Injection

- Compression

- Extrusion

- Sulfur

- Other

- Optional