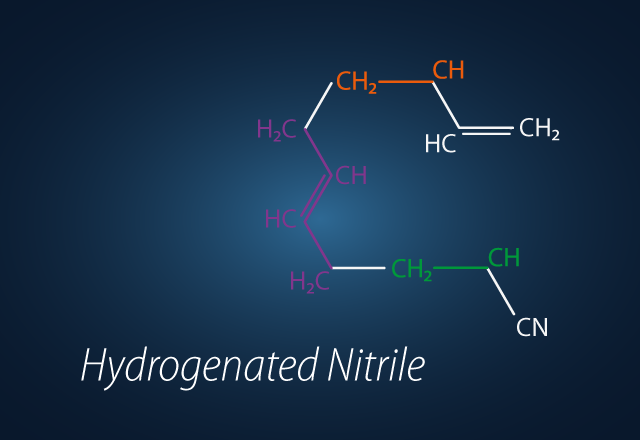

HNBR

HNBR is obtained by the hydrogenation of NBR (nitrile rubber), a process that provides it with superior resistance to higher temperatures, as well as oils and chemicals. HNBR exhibits excellent performance against oils and fuels, while also offering high resistance to steam, hot water, ozone, and a wide range of chemicals.

Additionally, its mechanical properties are notably strong. This material is distinguished by its high tensile and tear strength, as well as its elongation capacity and abrasion resistance.

Applications

HNBR is widely preferred in the automotive, industrial applications, oil and gas industries, and the food, pharmaceutical, and medical markets. In the automotive sector, it is commonly used in dynamic and static seals, hoses, belts, coolants, AdBlue systems, and oil and fuel systems. In industrial applications, HNBR plays a crucial role in sealing materials used in oilfield exploration and processing, as well as in rollers found in steel and paper mills.

HARDNESS RANGE:

30to 90 Shore A

- Hydrogenated Nitrile Butadiene

- Injection

- Compression

- Extrusion

- Peroxide

- Sulfur

- Optional