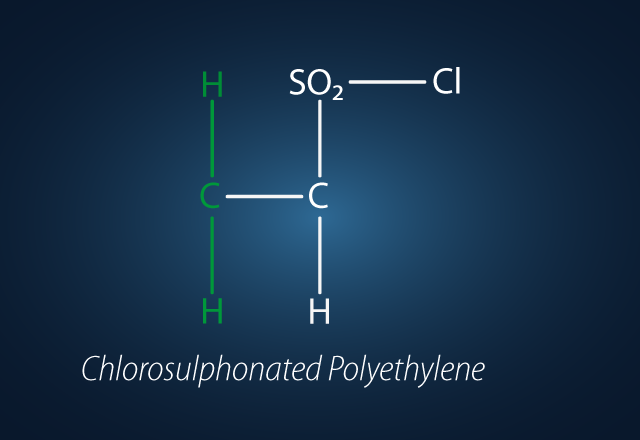

CSM

Chlorosulfonated Polyethylene (CSM), commonly known under the Hypalon brand, is a rubber material considered superior to chloroprene in some aspects. CSM rubber offers advantages such as better thermal aging resistance, higher chemical resistance, and lower gas permeability. Containing approximately 20% to 45% chlorine, CSM rubber exhibits excellent resistance to ozone, UV rays, weathering, and chemicals. It is also resistant to oxidative agents and abrasive chemicals and gains hot water resistance when vulcanized.

CSM elastomer has several key properties that make it suitable for hazardous environments. High resistance to ozone, UV, weathering, and chemicals, good thermal aging resistance, and low gas permeability are among these features. Similar to chloroprene, it has poor flexibility at low temperatures, but its chemical resistance is high. However, due to its low resistance to fuels, it is not suitable for automotive applications. Additionally, CSM rubber’s poor compression set makes it unsuitable for dynamic sealing applications. CSM can be used in operating temperatures ranging from -20°C to +125°C.

Applications

CSM (Chlorosulfonated Polyethylene) elastomer is widely used in various industries and components due to its excellent chemical and weather resistance. The most common sectors and components include:

• Automotive and Transportation Sector:

CSM is typically used in parts requiring durability against external conditions, such as fuel hoses, cable sheaths, and seals. However, it is not widely used in automotive fuel systems due to its low resistance to fuels.

• Construction and Roofing Systems:

CSM is utilized in roofing membranes and waterproofing materials. Its resistance to UV, ozone, and weathering makes it ideal for such applications.

• Industrial Hoses and Coatings:

It is commonly used in environments exposed to abrasive chemicals, such as chemical-resistant hoses, protective coatings, and tank linings.

• Electrical and Cable Industry:

CSM is preferred for the outer sheathing of electrical cables, especially those used outdoors. Its high resistance to heat and environmental factors makes it an ideal material.

• Marine and Aerospace Sectors:

In these industries, CSM is used in various components of boats and aircraft due to its resistance to harsh weather conditions and seawater.

• Protective Clothing and Equipment:

CSM is chosen for protective gloves, garments, and equipment used in environments requiring high chemical resistance.

HARDNESS RANGE:

50 to 90 Shore A

- Chlorosulfonated Polyethylene

- Injection

- Compression

- Other

- Yes