FKM

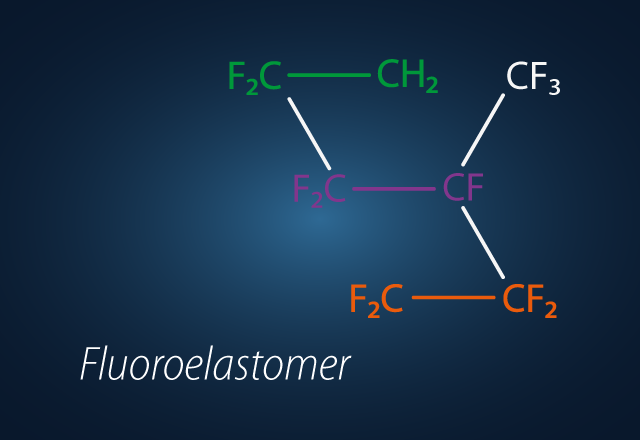

Fluoroelastomers provide the highest resistance to fire and chemicals among rubber types due to their high fluorine content and the structural stability of the carbon-fluorine bond. The commercial forms of these elastomers are obtained through radical polymerization of vinyl monomers. The most commonly used monomers include vinylidene fluoride (VDF), tetrafluoroethylene (TFE), hexafluoropropylene (HFP), perfluoromethylvinylether (PMVE), 2-methoxyethylvinylether (MOVE), ethylene, and propylene.

Improvements in mechanical properties and chemical resistance, enhanced low-temperature performance, adjustment of cross-linking types, and optimization of processability are achieved by adding groups with varying steric hindrance into the polymer chain in appropriate ratios and using special end groups.

Applications

• O-ring seals for fuel distribution systems, lubricants, and chemicals

• Rotary shaft seals

• Manifold gaskets

• Valve seals

• Gaskets

• Hoses and pipes for fuel and lubricant systems

• Turbocharger hoses

• Fuel tank bladders

• Rollers

• Component parts for the semiconductor industry

HARDNESS RANGE:

50to 95 Shore A

- Fluoroelastomer

- Injection

- Compression

- Peroxide

- Other

- Evet