CR

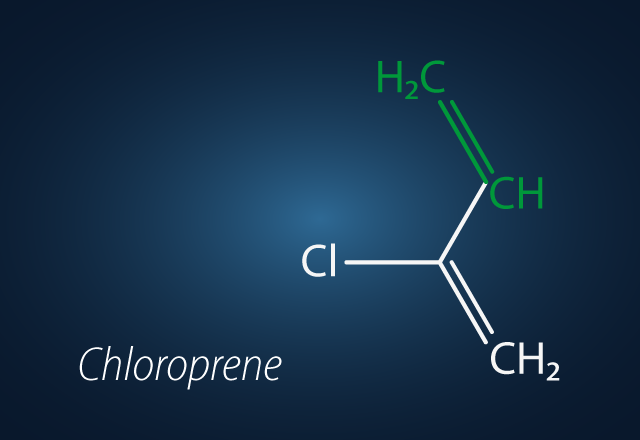

Chloroprene rubber, also known as Neoprene (DuPont’s trade name), is produced by the polymerization of 2-Chloro–1,3-butadiene monomer. This polymerization typically occurs in the trans 1,4 configuration, and the crystallization rate of CR depends on the amount of trans configuration in the polymer. CR, classified into general-purpose, adhesive, and latex types, may not surpass advanced elastomers in any single property. However, the combination of its properties is unmatched by other elastomers.

CR types differ based on crystallization tendency, polymer viscosity, the degree of pre-crosslinking, and the modifying agents used during polymerization. As the crystallization tendency increases, raw strength, tensile strength, and modulus values rise. Additionally, properties such as fatigue resistance and elasticity are enhanced.

Increasing Mooney viscosity provides higher extensibility with fillers and oils, dimensional stability, raw strength, mechanical properties, tear resistance, modulus, and resistance to permanent deformation.

CR can also be blended with other polymers. Adding NR improves elasticity, BR lowers the glass transition temperature and enhances processability, while NBR increases resistance to swelling in oils.

Applications

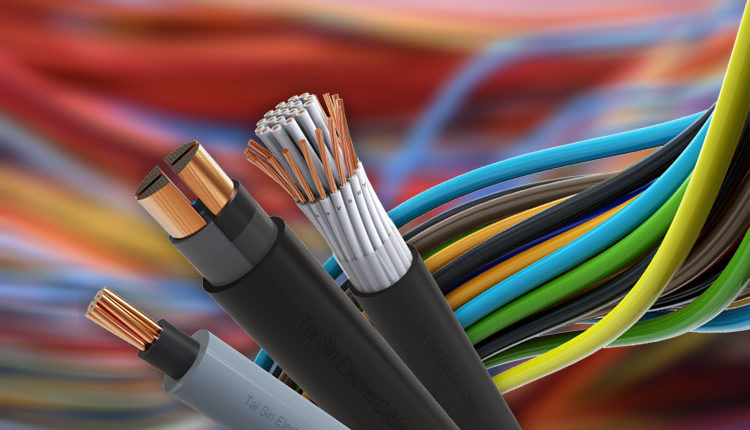

Chloroprene rubber is used in a wide range of applications, including air conditioner hoses, seals, and wipers, power cables, fuel hoses, rollers, transmission belts, and corrosion-resistant coatings. It is also preferred as a base material for adhesives. Protective suits for divers represent another significant application area for CR rubber.

HARDNESS RANGE:

20 to 90 Shore A

- Chloroprene

- Injection

- Compression

- Extrusion

- Sulfur

- Other

- Optional