AEM

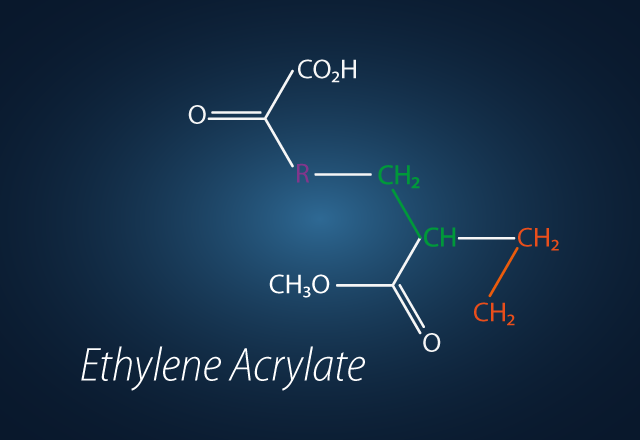

AEM rubber is a synthetic rubber created by combining ethylene and acrylic monomers. Ethylene provides excellent properties at low temperatures, while the acrylic component enhances oil resistance. The combination of a saturated backbone structure with polar side groups results in high resistance to heat, ozone (weathering), and many chemicals.

In addition to its excellent resistance to heat and ozone, AEM exhibits exceptional vibration damping capabilities across a wide temperature range, along with good dynamic and wear properties. However, compared to standard elastomers such as NR, NBR, CR, EPDM, and SBR, AEM is more expensive.

Applications

AEM elastomers are preferred in applications requiring resistance to ozone, heat, and oils. They are a cost-effective alternative to more expensive heat-resistant elastomers like fluoroelastomers (FKM) and fluoro-silicones (FVMQ) for high-temperature applications up to 190°C.

Typical applications of AEM elastomers include turbocharger hoses and other hose systems, crankcase gas and diesel particulate filter sensor covers, and air management components. Additionally, they are used in oil- and heat-resistant vibration dampers, engine and transmission seals, cylinder head gaskets, oil filters, oil pan gaskets, and gear pistons.

HARDNESS RANGE:

50 to 80 Shore A

- Ethylene Acrylic

- Injection

- Compression

- Extrusion

- Peroxide

- Other

- Evet