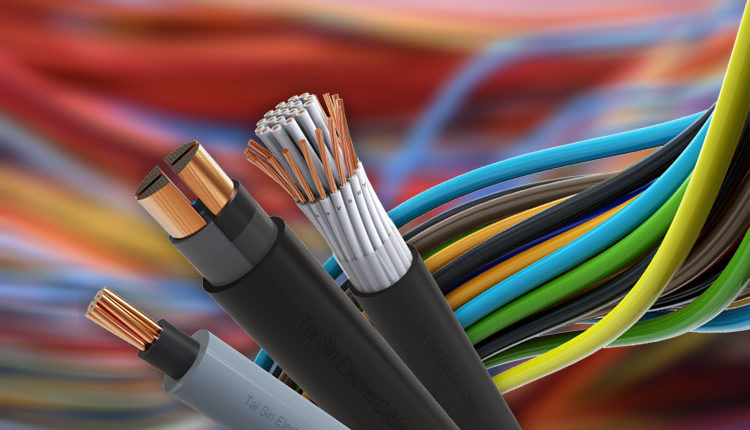

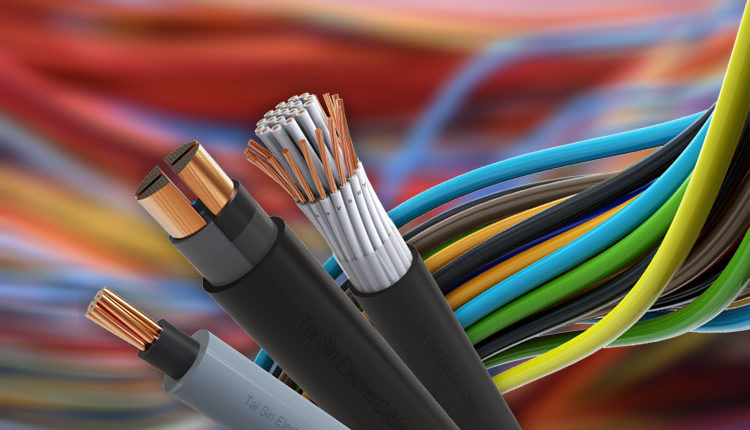

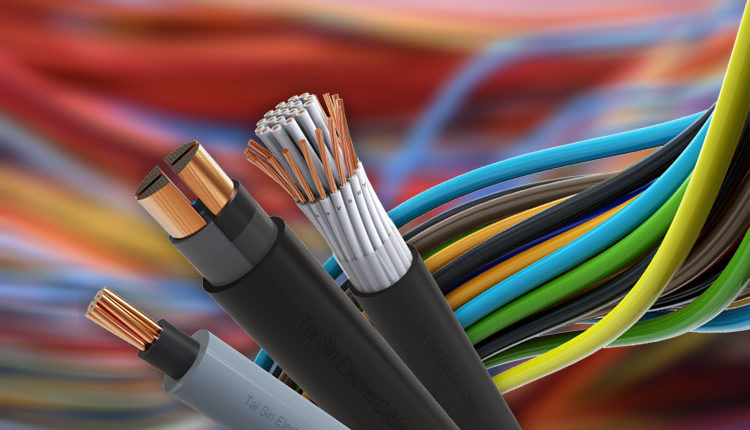

The cable industry requires materials that can deliver reliable and durable electrical and mechanical performance. Rubber materials are preferred for their flexibility, insulation properties, and resistance to heat and harsh environmental conditions. Rubber-based insulation and outer sheathing materials ensure the safe and long-lasting use of cables in various environments. By enhancing cable safety during energy transmission and signal transfer, rubber materials offer excellent resistance to chemicals, extreme temperatures, and moisture.

Key Rubber Materials Used in the Cable Industry

EPDM (Ethylene Propylene Diene Monomer): EPDM rubber is widely used in the cable industry due to its excellent electrical insulation properties and high resistance to ozone, UV rays, chemicals, and heat. Known for its high-temperature tolerance, EPDM is ideal for cables exposed to outdoor conditions, industrial power cables, and automotive applications.

Neoprene (Chloroprene Rubber, CR): Neoprene is known for its resistance to oils, chemicals, and weathering. It is commonly used as an outer sheath in industrial and marine cables. Neoprene’s abrasion resistance and flexibility ensure long service life and durability in demanding environments.

Silicone: Silicone maintains flexibility even under extreme temperatures and provides high electrical insulation. It is often used in fire-resistant cables and in environments requiring high-temperature resilience. Its biocompatibility also makes it suitable for cables supplying energy to medical devices.

Nitrile Rubber (NBR): Nitrile rubber is known for its resistance to oils, making it ideal for cables exposed to petroleum-based oils. It is used in heavy industry, mining, and marine cables that operate in oily environments.

Applications of Rubber Materials in the Cable Industry

Insulation and Outer Sheathing: Rubber materials are used for cable insulation and sheathing, providing electrical insulation that ensures the safe transmission of energy and minimizes short-circuit risks.

Flame-Retardant Cables: Fire-resistant cables often use flame-retardant silicone and EPDM rubber. These materials enhance safety by not releasing toxic gases during a fire and are widely used in building cable installations.

Flexible Cables: Rubber materials such as silicone, EPDM, and neoprene provide flexibility, allowing cables to bend and move easily. This is particularly advantageous for cables used in portable electrical devices and moving equipment.

Industrial Power Cables: EPDM and neoprene rubber are used in high-voltage industrial power cables as outer sheathing materials. These materials resist chemicals and mechanical impacts, extending the service life of cables and reducing maintenance costs.

Marine and Outdoor Applications: Neoprene rubber, with its high resistance to UV and water, is preferred for marine cables. These cables remain durable even in high-salinity environments such as seawater.

High-Temperature Applications: Silicone rubber is used in heat-resistant cables for high-temperature environments. Applications include ovens, motors, and industrial facilities requiring cables that can withstand intense heat.